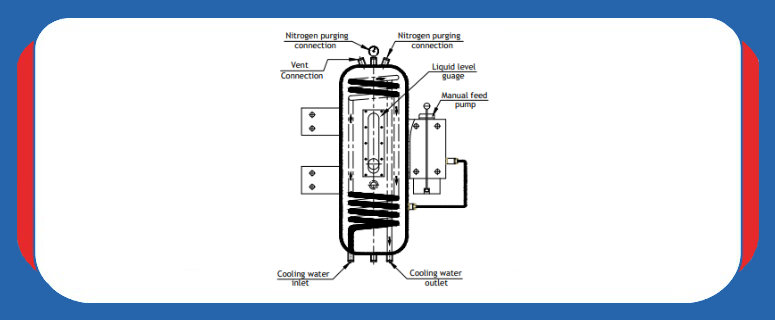

THERMOSYPHON POT

MSTS

We are leading manufacturer of Thermosyphon Pot those are made by high grade of material. We are dedicatedly engaged in offering a qualitative assortment of Thermosyphon Seal Pot to our valued patrons, across the country. It designed for generally industry applications. Thermosyphon Pot finds application is supplying barrier fluid & pressurising double & tandem mechanical seals. It is equipped with all necessary connections & fittings to suits new requirements after installation. This Thermosyphon Seal Pot is vastly used in domestic markets. We offer these products in varying shapes, sizes and designs. Client Purchase these at reasonable rate.

STANDARD TYPE

METAL PARTS

- Thermosyphon shell: Carbon steel,SS 316 L,

- Cooling coil: SS 316 L , SS 304

- Secondary seal: Elastomers

OPERATING LIMITS

- Capacity: 7.5,10,12, 20 ltrs

- Design pressure: 40 bar

- Hydraulic test pressure: 60 bar

- Working temperature (max.): 180??C

- Heat transfer area of cooling coil: 0.226m??

- Cooling water flow rate recommended: 10 ltrs/min

CONNECTION SPECIFICATIONS

- Cooling water inlet ...........1/2" NPT(F)

- Cooling water outlet .........1/2" NPT(F)

- Barrier fluid inlet ..............1/2" NPT (F)

- Barrier fluid outlet ............1/2" NPT (F)

- Pressure guage connection...3/8" NPT (F)

- Filling connection ..............1/2" NPT (F)

- Nitrogen purging connection..1/2" NPT (F)

- Feed pump connection ........1/4" NPT (F)

- Drain ..............................1/2" NPT (F)

ACCESSORIES

- Pressure guage : 0-10, 0-25, 0-40 bar

- Level guage : To indicate barrier fluid

- Manual feed pump : 2 ltrs (optional)

This is used for double mechanical seals in tandem or back to back arrangement to provide necessary lubrication and cooling to the seal faces to achive recommended seal life and comes equipped with cooling coil inside the shell to bring down the temperature of barrier fluid coming from seal to thermosyphon.

Our Products

- API Seals Type A Arrangement - 1

- API Seals Type B Arrangement - 1

- API Seals Type C Arrangement - 1

- Multi Spring Seals Multi Spring Balanced

- Spring Out of Product Seals

- Stationary High Pressure Seals

- Split Seals

- Conical Spring Seals

- Single Spring Unbalanced

- PTFE Bellow Seals

- Rubber Bellow Seals MSG1, MSG12, MSG13

- Stationary Metal Bellow

- Gas Lubricated Seals

- Dry Running Seal

- Agitator Seals Single Agitator Seals

- Bearing Isolator

- Rotary Joint

- Thermosyphon Pot

- Cryogenic Seals

- Double Mechanical Seals For Anfd

- Mating Ring

- Flushing Plans API-682

Arrangement - 2

Arrangement - 3

Multi Spring Unbalanced

Multi Spring Balanced

Unbalanced With Lug

Balanced

MSR60

Double Agitator Seals

Information Data

Contact Us

MAFFS Seals

Factory Address:

Factory Address:Gala No. 72, Shorab Compound, R.M. Road,

Oshiwara, Jogeshwari (W), Mumbai 400102, India.

Regd Office Address:

Regd Office Address:303, Badhra Apartment, Western Park, Misquita Wadi,

Western Express Highway No. 8, Mira Road (East),

Dist. Thane 401107, India.

Mobile No:

Mobile No: +91-98205 68022

Email:

Email:sales@maffsseals.com

© 2021 www.maffsseals.com | All Rights Reserved.MAFFS

![]()