GAS LUBRICATED SEALS

MSCGS

Gas seals run in a clean, controlled fluid environment and are designed to remain non-contacting and non-wearing for the expected operating conditions. Gas lubricated mechanical seals produce consistent seal performance, even in a widely varying duty cycle, and reduce power consumption at the seal faces. The seal generates little heat, and any gas leakage absorbs heat away through gas expansion. It is imperative that the seal faces are separated with a gas barrier film. If the faces contact, the seal will not last long running dry at typical pump speeds.

Product Description:

- For stepped shafts

- Balanced

- Gas-lubricated

- Rotating spring

- Standard version with U-grooves, V-grooves opt.

APPLICATIONS: (Typical Industrial)

- Gases (single seals only gas)

- Refining technology

- Chemical industry

- Small steam turbines

- Roots compressor

OPERATING CONDITIONS:

- Shaft diameter: 28 125mm

- Pressure: Vacuum: 25 bar (max)

- Temperature: -20??C...+170??C

- Speed : 25 m/s

FACE MATERIALS:

- Carbon/ Silicon Carbide/Tungsten Carbide, Metallic Carbon

METAL PARTS:

- SS 316, SS 304

ELASTOMERS:

- VITON, EPDM, FFKM

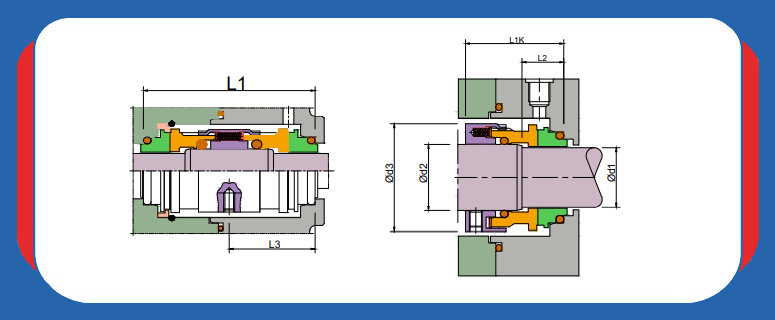

| ??d1 | ??d2 | ??d3 | L1K | L2 | L3 | L4 | |

| 28.0 | 33.0 | 53.5 | 50.0 | 20.0 | 44.5 | 89.5 | |

| 30.0 | 35.0 | 55.5 | 50.0 | 20.0 | 44.5 | 89.5 | |

| 32.0 | 38.0 | 60.5 | 50.0 | 20.0 | 44.5 | 89.5 | |

| 33.0 | 38.0 | 60.5 | 50.0 | 20.0 | 44.5 | 89.5 | |

| 35.0 | 40.0 | 62.5 | 50.0 | 20.0 | 44.5 | 89.5 | |

| 38.0 | 43.0 | 65.5 | 52.5 | 23.0 | 47.5 | 95.5 | |

| 40.0 | 45.0 | 67.5 | 52.5 | 23.0 | 47.5 | 95.5 | |

| 43.0 | 48.0 | 70.5 | 52.5 | 23.0 | 47.5 | 95.5 | |

| 45.0 | 50.0 | 72.5 | 52.5 | 23.0 | 47.5 | 95.5 | |

| 48.0 | 53.0 | 75.5 | 52.5 | 23.0 | 47.5 | 95.5 | |

| 50.0 | 55.0 | 77.5 | 57.5 | 25.0 | 52.0 | 104.5 | |

| 53.0 | 58.0 | 84.5 | 57.5 | 25.0 | 52.0 | 104.5 | |

| 55.0 | 60.0 | 86.5 | 57.5 | 25.0 | 53.0 | 106.5 | |

| 58.0 | 63.0 | 89.5 | 62.5 | 25.0 | 56.0 | 112.5 | |

| 60.0 | 65.0 | 91.5 | 62.5 | 25.0 | 56.0 | 112.5 | |

| 63.0 | 68.0 | 94.5 | 62.5 | 25.0 | 56.0 | 112.5 | |

| 65.0 | 70.0 | 97.5 | 62.5 | 25.0 | 56.0 | 112.5 | |

| 70.0 | 75.0 | 104.5 | 70.0 | 28.0 | 63.0 | 126.5 | |

| 75.0 | 80.0 | 109.5 | 70.0 | 28.0 | 63.0 | 126.5 | |

| 80.0 | 85.0 | 114.5 | 70.0 | 28.0 | 63.0 | 126.5 | |

| 85 | 90.0 | 119.5 | 75.0 | 28.0 | 63.0 | 126.5 | |

| 90 | 95.0 | 124.5 | 75.0 | 28.0 | 63.0 | 126.5 | |

| 95 | 100.0 | 129.5 | 75.0 | 28.0 | 63.0 | 126.5 | |

| 100.0 | 105.0 | 132.5 | 75.0 | 28.0 | 63.0 | 126.5 | |

| 105.0 | 115.0 | 153.5 | 73.0 | 32.0 | 68.0 | 136.5 | |

| 110.0 | 120.0 | 158.5 | 73.0 | 32.0 | 68.0 | 136.5 | |

| 115.0 | 125.0 | 163.5 | 73.0 | 32.0 | 68.0 | 136.5 | |

| 120.0 | 130.0 | 168.5 | 73.0 | 32.0 | 68.0 | 136.5 | |

| 125.0 | 135.0 | 173.5 | 73.0 | 32.0 | 68.0 | 136.5 | |

Our Products

- API Seals Type A Arrangement - 1

- API Seals Type B Arrangement - 1

- API Seals Type C Arrangement - 1

- Multi Spring Seals Multi Spring Balanced

- Spring Out of Product Seals

- Stationary High Pressure Seals

- Split Seals

- Conical Spring Seals

- Single Spring Unbalanced

- PTFE Bellow Seals

- Rubber Bellow Seals MSG1, MSG12, MSG13

- Stationary Metal Bellow

- Gas Lubricated Seals

- Dry Running Seal

- Agitator Seals Single Agitator Seals

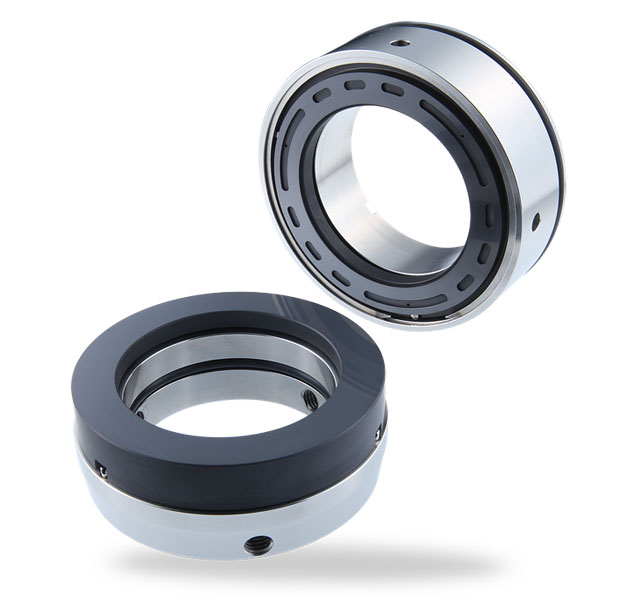

- Bearing Isolator

- Rotary Joint

- Thermosyphon Pot

- Cryogenic Seals

- Double Mechanical Seals For Anfd

- Mating Ring

- Flushing Plans API-682

Arrangement - 2

Arrangement - 3

Multi Spring Unbalanced

Multi Spring Balanced

Unbalanced With Lug

Balanced

MSR60

Double Agitator Seals

Information Data

Contact Us

MAFFS Seals

Factory Address:

Factory Address:Gala No. 72, Shorab Compound, R.M. Road,

Oshiwara, Jogeshwari (W), Mumbai 400102, India.

Regd Office Address:

Regd Office Address:303, Badhra Apartment, Western Park, Misquita Wadi,

Western Express Highway No. 8, Mira Road (East),

Dist. Thane 401107, India.

Mobile No:

Mobile No: +91-98205 68022

Email:

Email:sales@maffsseals.com

© 2021 www.maffsseals.com | All Rights Reserved.MAFFS

![]()